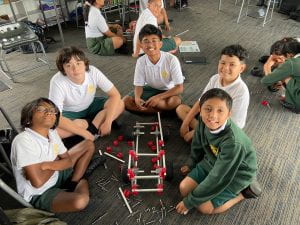

Last Friday, My class and I began our final Epro8 project. Building a playground. We first had to decide what equipment we were going to make. We planned to make a swing, seesaw, slide and merry-go-round. Since it would be quite a hefty task, each group could now use two Epro8 boxes. Our group of four split into twos, each duo would work on a piece of equipment. Me and one of my friends worked on the merry-go-round while the other two worked on the swing,

We decided to take inspiration from a real park to design the merry-go-round. Of course, we weren’t master engineers so the final product was very chunky and seemed to always malfunction in some way or another. We started with the turning mechanism. The merry-go-round was to be a manual machine, we didn’t have the necessary materials to go for automation. We first had to make it turn, for this we used axles. From there we could build the rest of the merry-go-round, but it first needed a strong base. The base, once finished, was extremely rudimentary. It was pretty much a bundle of short, stubby legs. Despite it being very short and alarmingly unstable, it did its job…most of the time.

Occasionally, I glanced at what my other teammates were doing. Their job was going much smoother than ours. The swing was pretty basic, a seat attached with axles to the main body. After a quick water break, My friend and I resumed building. The merry-go-round we had in mind wasn’t exactly what we had planned. We would have never had enough materials to make an actual merry-go-round. What we were building was more of a single wide seat that spun rapidly. We began building the super wide seat which would hold our playground tester.

This is him ( I know, the picture is pretty low quality)

This seat would turn out to be the most complicated thing in the entire project. We struggled a lot and had to cut corners more than a few times. Surprisingly, we were lacking in materials even with two whole boxes of equipment. Due to this, we had a very hard time building the seat. For some reason, we decided to make the seat super wide. It didn’t have to be, we just did. We learned this was a terrible mistake the hard way, when we ran out of long bars. In the end, we built everything with extended medium bars. Once finished, we had our playground tester give it a spin. Unsurprisingly, it failed after a few seconds of spinning.

My other teammates finished way earlier, and had already built the slide and made good progress in the seesaw. We were able to finish up the entire project a couple minutes later. Before we shared our wonderful creations with the class, our tester had some business to attend to.

The swing worked fine, although the seat was abnormally small. The slide went fine, but it could’ve been steeper. Finally, the see saw was miniature compared to the other builds. We had essentially run out of any building materials, but we managed to scrape by. Now it was time to present to the class. The first group had built a seesaw, swing and merry-go-round. Their seesaw was much larger and mechanical than ours, and their swing had two big seats. The merry-go-round they had built was much smaller and less complicated than ours.

My group was up next. During the presentation, Mrs George took pictures for us to use in our blogs. To help us present to the class, we had our playground tester use some of the equipment. It took us about three tries to do the presentation, mostly because our tester had difficulty fitting in the swing. The next group had compacted all their builds in one mega-build. I can’t quite remember what builds they had, but I do know they had a slide and a flying fox.

With the presentation finished, we started the very long, very mundane disassembling process. It was the last time we would ever be disassembling, so the mood was pretty glum. The lights were off, no one was talking. The process as a whole was monotonous and uncomfortably painful. We put everything back and gave the boxes to room 7 for them to use.

I’d rate the experience a solid 8/10. I could definitely see myself wanting to do it again.